The ocean shipping industry has undergone many changes over the years, especially concerning container vessel technologies, and the trend with modern ships is that they are increasingly larger than their older and outdated predecessors. As a result, port and terminal handling equipment need to be updated and enlarged alongside the growing size of container ships.

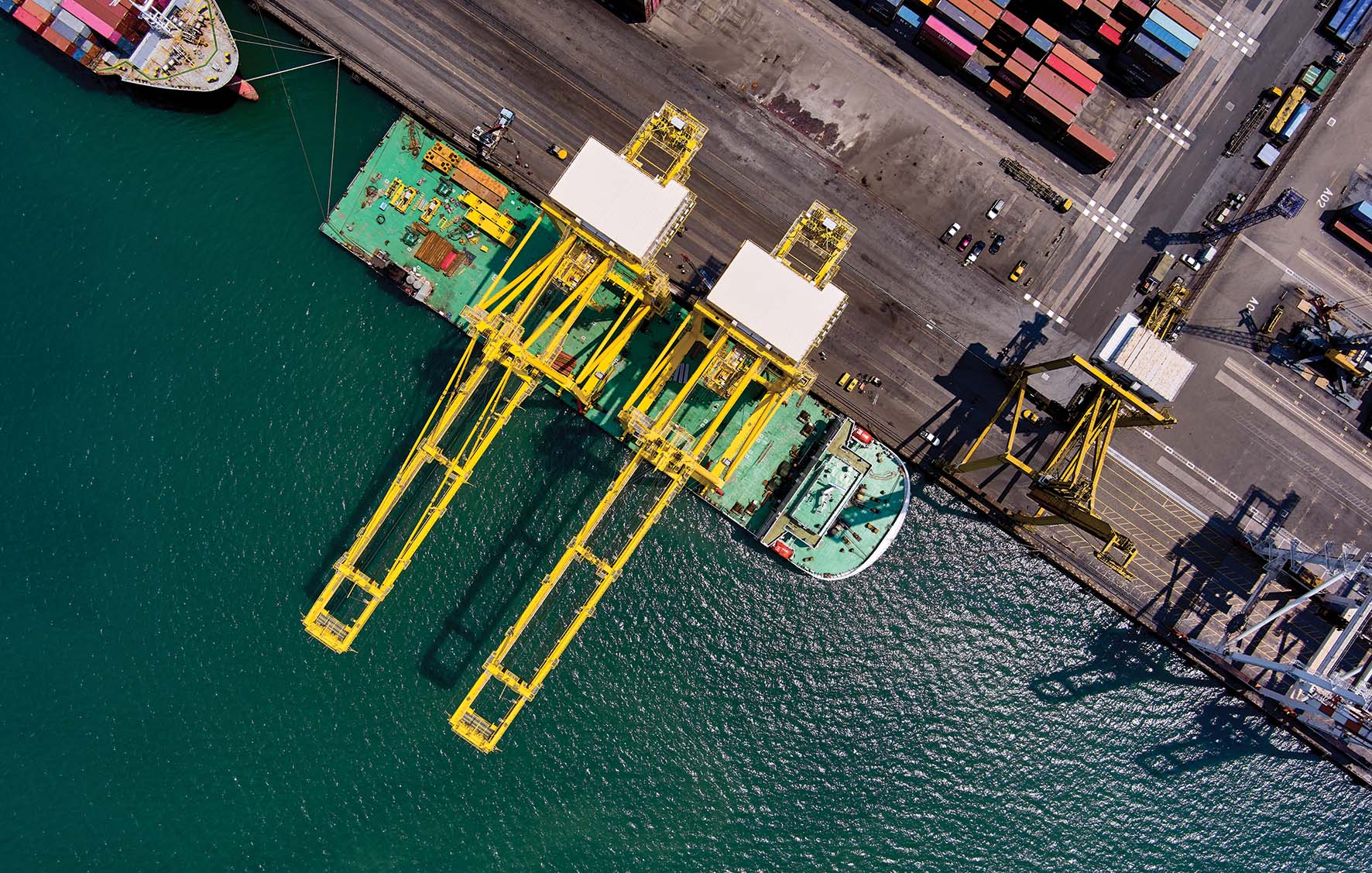

Feeling the wind, TIPS, the private terminal operator at Laem Chabang Port, took a significant step in upgrading its shoreside operations with two modern ‘SANY’ ship-to-shore (STS) cranes, ensuring it will be ready to serve larger ships that come ashore. The new equipment will increase operational speed and safety and help increase container capacity at Laem Chabang Port.

Back in the Day

TIPS B4 terminal currently operates with 5 STS cranes, including 2 Post Panamax cranes with 50-ton load capacity and 3 Panamax cranes with 37.5-ton load capacity. Two of the latter, which the Port Authority of Thailand (PAT) provided, have been in service since the terminal’s first day of operation in 1991.

With only 13 rows across the board, the Panamax cranes are restricted by their size and are approaching the limits of their operational effectiveness.

Furthermore, the two cranes provided by the PAT have now passed their prime and require more than usual care and attention, resulting in operational interruptions. Thus, the decision to acquire new cranes is as wise as it is necessary, especially when operating along major trade lanes.

Reinforced with new cranes

The new STS-605201 Post Panamax cranes are supplied by SANY, a leading cargo handling manufacturer in China. The cranes are made in SANY Zhuhai Industrial Park in Zhuhai, China, and the whole manufacturing process spanned 14 months before they were shipped and arrived safely at the B4 terminal on March 6th, 2022.

Powered with 60 tons lifting capacity, 52 meters in boom length, and 15-meter reverse reach, the new cranes can achieve 50 moves per hour, a whopping increase of over 40% in performance. Consequently, the SANY STS cranes are considered TIPS’ most efficient pieces of equipment, and their arrival is paving the way for TIPS on its journey to modernise its operations and become one of Thailand’s most successful terminals, as well as putting them on par with leading terminals globally.

Performance aside, the new SANY STS cranes are built with Semi-Automation capabilities and are Remoted Control upgradable. The customised BROMMA Spreader on the cranes comes with CCTV to assist the crane operator. The spreader is also equipped with 8 spot-weighing sensors to help increase lifting efficiency, along with work safety.

“The new cranes will replace the current ones which have been in service for a long time. Not only will they help increase shoreside efficiency, improve work safety, and shift the level of technology for our terminal, but with the planned adoption of remote-control capability in the future, we will be among the most modern facilities in Southeast Asia,” said Capt. Chatchawan Ghettalae, Managing Director, TIPS.

He added, “Purchasing the new cranes is one of the most important investments in our infrastructure. The move reflects our dedication to serve our customers better and help promote Thai importers and exporters on the global stage. Moreover, it will support Laem Chabang Port on its mission to become a regional hub in Southeast Asia.”

อัพเดตข่าวสารและบทความที่น่าสนใจในอุตสาหกรรมโลจิสติกส์ก่อนใคร ผ่าน Line Official Account @Logistics Mananger เพียงเพิ่มเราเป็นเพื่อน @Logistics Manager หรือคลิกที่นี่