The current exponential growth in the logistics industry has compelled numerous service providers to discern their unique strengths. This is essential for elevating service standards beyond competitors in the market and ensuring the steadfast trust of customers.

For Hutchison Ports Thailand (HPT), the commitment to delivering unrivalled standards has been one of the company’s core values, particularly in establishing new benchmarks for the industry and fostering innovations that enhance transportation processes.

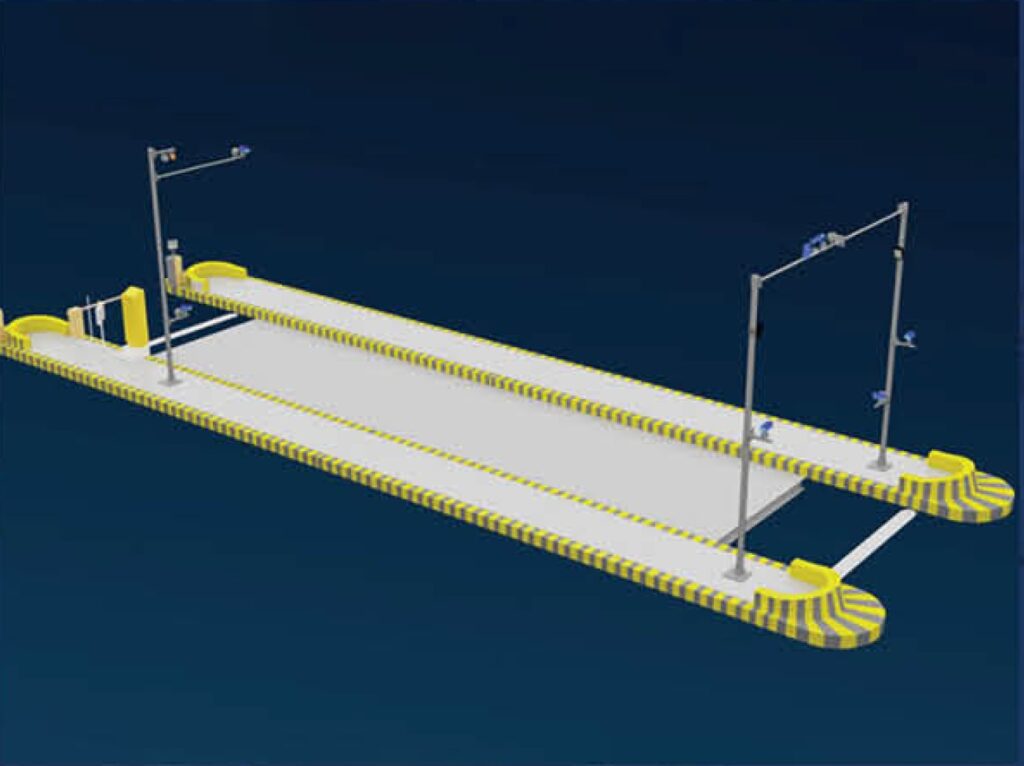

In 2023, HPT developed an Automated Gate Operation System as an innovative solution resulting from the fusion of the self-service concept with state-of-the-art hardware technology and a seamless operational process. This advancement aims to elevate the service standards at HPT’s Terminals.

The Self-Service Concept

The concept of self-service aims to streamline operations by minimising intermediary steps, allowing customers to access information or services independently without needing staff assistance.

In the case of cargo container inspection at the terminal gates, traditionally, the truck driver would have to submit relevant documents related to the containers’ pickup and delivery to the inspection gate officer. They would have to wait for document verification, container condition check, seal number inspection, and trailer registration, among other processes. After completing the inspection, they would receive the paperwork, queue, and position for picking up and delivering the containers in the yard.

Despite the professionalism of the documentation staff at the gate, these processes can create significant negative factors for operations, from incomplete or inaccurately filled documents leading to extended processing times at the inspection gate. This, in turn, has a cascading impact on the waiting queue for other tractor-trailers near the gate.

The Turning Point from Technology Advancements

Since HPT commenced operations at the Laem Chabang Port, the company has invested steadfastly in state-of-the-art technology and modern equipment. To this day, HPT still persistently seeks ways to leverage these tools to continuously enhance the operational practices at thier terminals.

HPT has invested in hardware and technology for the Automated Gate Operation System to support the customers’ comprehensive self-service process. This includes:

- Optical Character Recognition (OCR) Technology: OCR is a technology that converts data from images into data files that can be used with other programs in the computer system. HPT has implemented OCR to capture data such as container information, numbers of container door seals, labels attached to the containers, and damages that may occur to the containers. The system then converts this information into data files sent to the automated gate operating system.

- RFID Tag Equipment: HPT uses RFID tags to identify the registration information of trucks entering and exiting. This is done by reading radio frequency signals through RFID readers and receiving responses from RFID tags installed on container trucks’ roofs or wind deflectors.

- Kiosk Machines: These machines issue entry slips upon entry through the automated gate and specify the container pickup and drop-off locations within the cargo container yard. This allows tractor-trailer drivers to deliver or pick up containers in the correct locations. Drivers can confirm their identity through the UBI application or by inserting their ID card into the card slot. The Kiosk cabinet then issues a slip immediately upon receiving complete information from the automated inspection gate.

The Unrivalled Standards

The most crucial aspect of embracing the new operational process to align with overall port operations is the robust and flexible structure of the port operating system. At the core of Hutchison Ports’ operation worldwide is the ‘nGen’ Terminal Operating System, a system designed and developed in-house to seamlessly connect vital information within the port operation process without any disruptions.

Integrating the Automated Gate Operation System into the nGen operating system has elevated the performance of each component, enabling efficient coordination. This includes rapidly and accurately connecting digital data at the inspection gate with the main operating system. This not only enhances transparency at the cargo inspection gate but also positively impacts the overall port operations, making them even more agile.

Nevertheless, HPT prioritizes user adaptability, maintaining a dedicated service team at the inspection gate. This ensures that truck drivers can fully benefit from these changes, aligning with HPT’s commitment to exceed customer expectations. With unrivalled standards, all services are designed to be convenient and comfortable for users across the spectrum, from shipping lines and freight forwarders to importers/exporters and truck drivers.

อัพเดตข่าวสารและบทความที่น่าสนใจในอุตสาหกรรมโลจิสติกส์ก่อนใคร ผ่าน Line Official Account @Logistics Mananger เพียงเพิ่มเราเป็นเพื่อน @Logistics Manager หรือคลิกที่นี่