Arvato Supply Chain Solutions continues to advance the automation of its locations. Recently, a driverless transport system (DTS) has been introduced to handle all floor-level pallet transport jobs for the healthcare sector at the Harsewinkel distribution center. The system includes six automated industrial trucks from Jungheinrich that can move around the space freely and deliver around 400 pallets a day to their destinations.

Among other things, Arvato uses its Harsewinkel location to deliver logistics services for customers in the pharmaceutical and medical technology industries, with 31,000 square meters available for this purpose at the site. To cope with the increasing volume of internal pallet transport tasks while also countering the shortage of skilled labor, the site has invested in six driverless transport trucks developed by the specialist Jungheinrich. For this purpose, around 300 reflectors were installed on the walls and shelves along the transport routes in the summer of 2019. These serve as navigation points for the vehicles and are recognized by a laser scanner on the vehicles. This enables the driverless transport vehicle (DTV) to navigate with an accuracy of up to two millimeters using triangulation.

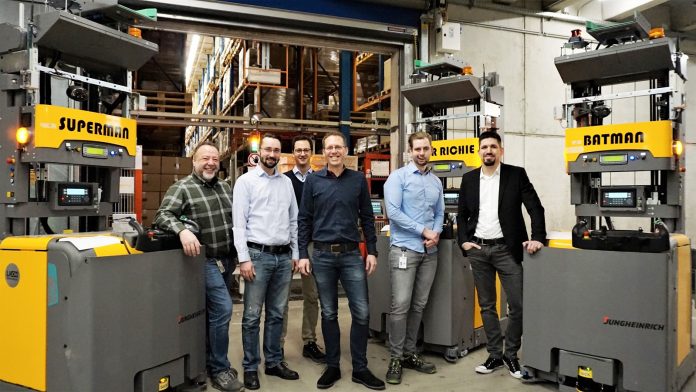

During the implementation phase, a new conveyor technology control system was installed, floor markings were applied in accordance with 5S standards, and turning stations and buffer racks were set up on the central travel track to automatically buffer pallets and map out longitudinal and transverse transport operations. The new technology is rounded off by system interfaces with the warehouse management software and the conveyor technology control system, plus new DTS-specific scanning dialogs. Employees working in Goods Receipt, Outgoing Goods, and Internal Transport were informed about the concept and the corresponding rules of conduct at the beginning of the year. The six vehicles, named after famous superheroes like Hulk, Batman or Superman, drive to all the site’s warehouses, Goods Receipt and Outgoing Goods, and also stop at the disposal area to empty the waste containers.

Driving jobs for the DTS are generated based on the transport jobs generated by the warehouse management software. The source and destination for the automatic system are generated via the respective source and destination storage locations. The DTVs navigate independently around the warehouse, open gates, and put pallet conveyor systems into operation.

“Thanks to the interfaces between the DTS, the warehouse management software and the conveyor technology, each pallet movement has an integrated status upgrade. This enables us to track the current position of a pallet in real time,” explains Erich Berg, Lead Project Manager at Arvato. In addition to this, the system also transports finished shipping pallets. The warehouse management software verifies whether there is already a loading row for the carrier or opens a new loading row and submits it to the control software.

“We can also provide the system with manual support at any time. With the help of a master computer, we can block off certain areas or hall sections in order to keep mixing between the traffic from the automated and manual halls to a minimum,” explains Matthias Anderson from the Logistics Engineering business unit. If an obstacle is in the way, the vehicle comes to an immediate stop and does not continue its task until the obstacle has been removed. The vehicle is also connected to the personal protection system, the high-speed doors, the fire protection doors and the fire alarm system. In the event of an alarm, the driverless transport system exits the danger zone independently.

“Driverless transport systems are the cornerstone of automated intralogistics. Based on tried and tested standard industrial trucks supplemented by automation components and controlled by intelligent software, they perform recurring transport tasks for high handling volumes extremely safely and efficiently. The EKS 215a, which Arvato is currently using, is a driverless transport vehicle based on the EKS vertical order picker. The EKS 215a can transport loads of up to 1.5 t in weight and automatically store them at lifting heights of up to 6.0 m. In the process, the vehicle can reach maximum speeds of up to 2.5 m/s. At Arvato, the vehicle travels at a speed of 1.7 m/s and the lifting height is 2.5 m.The elimination of the driver’s platform makes the EKS 215a particularly maneuverable, even in confined spaces. The self-supporting forks of the EKS 215a enable it to transport special load carriers and closed pallets, as well handling stations that we can’t drive vehicles under,” says Dr. Markus Heinecker, Project Sales Manager at Jungheinrich.

“The implementation of the Driverless Transport System provides optimum support for our employees,” said Fabian Generotzky, Director of Operations at Arvato Supply Chain Solutions. “They can devote themselves to more value-creating activities and put their energy into tasks such as stocking the reserve warehouses so that goods can be retrieved more quickly. As well as being innovative, this also increases the level of quality in the warehouse. Damage to pallets is minimized because the system works with millimeter precision.

Alongside VVA in Gütersloh and the Arvato logistics center in Landsberg, the Harsewinkel facility is one of the pioneers in this field. “Given the great depth of integration into the processes and the associated complexity, I am sure that this project can be used as a prime example for the further expansion of automation at Arvato,” Project Manager Berg says.

อัพเดตข่าวสารและบทความที่น่าสนใจในอุตสาหกรรมโลจิสติกส์ก่อนใคร ผ่าน Line Official Account @Logistics Mananger เพียงเพิ่มเราเป็นเพื่อน @Logistics Manager หรือคลิกที่นี่