As a direct result of the pandemic, the demand for e-grocery has risen by more than 60%. Warehouses across the country struggled to cope with the sudden influx of orders. It soon became clear that even a guaranteed system availability of almost 100% doesn’t mean the flow of goods can handle a big jump in order volumes.

With a McKinsey report showing these grocery-shopping habits will stick, it is important to ensure your system keeps pace. This requires an intelligent software solution approach based on real-time analytics.

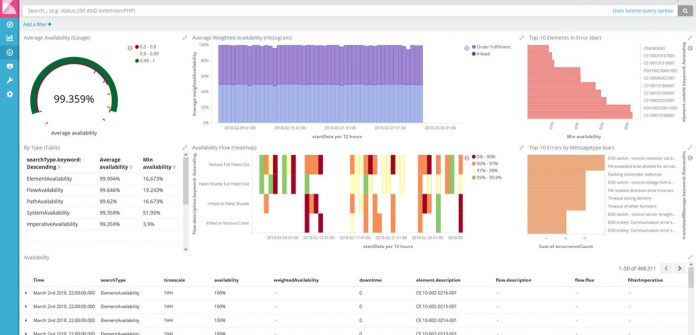

SynQ Availability Manager from Swisslog offers an intelligent solution for forward-looking availability planning. The software provides a holistic view of how optimal each machine works in isolation and collectively within the warehouse workflow. It identifies the exact availability of every element and workflow in the warehouse. This provides a seamless overview of the entire system, allowing the visibility to take action to avoid downtime. It also allows warehouse managers to plan service and maintenance with a higher degree of accuracy while focusing on the more important maintenance tasks.

Focus on optimization

“Availability Manager makes use of the proven SynQ 3D Visualizer,” says Stuart Dunn, Product and Key Account Manager at Swisslog. “The intuitive interface offers a 3D overview of all areas in an automated warehouse. Whether it is cranes, CarryPick, shuttles, or conveyors – the software can access its availability data. It then compares this against the throughput data in an ongoing process.”

Based on each warehouse element’s status, a comprehensive picture emerges, highlighting the availability of the entire material flow system. Any time frame can be analysed, from hours to weeks and from a historical analysis to live data. It also allows the defining of configurable shift patterns within the operation to focus on specific KPIs.

“For instance, it allows system operators to compare target vs. actual availability and offers a realistic assessment of whether the warehouse is performing sufficiently to fulfil orders,” Stuart adds. Elements critical to the entire system are immediately identified to optimize maintenance and spare parts management proactively. This means eliminating bottlenecks early on and cutting the costs associated with downtimes and delivery delays.

Planning and commissioning

In the planning process of designing a new logistics centre, Swisslog experts work out exactly how much warehouse capacity is needed and how many pallets or bins will go through the system each hour.

To maintain the required delivery capability, their experienced system designers allow additional reserve capacity beyond the actual demand to cover order peaks and any growth plans. “This allows us to guarantee the necessary availability and ensure that our systems will achieve the expected throughput at an optimal cost-benefit ratio”, says Stuart. “Swisslog experts can then link this with contractual commitments, giving the customer peace of mind for future operations.”

From the time you start up your new system, the Availability Manager for SynQ is ready to measure whether the system can meet the planned availability targets and report on this via the SynQ Cockpit. Swisslog has also used the tool to validate commissioning and integration data ahead of production go live.

“Most competing tools focus on the availability of individual mechanical elements and provide data only on whether each element of the system will meet performance requirements,” Stuart explains. “The Availability Manager, on the other hand, gets right to the heart of the matter: the availability of all material flow and business processes through a data-driven approach to operational events captured through SynQ.”

Ongoing operation and maintenance

Should the flow of goods be interrupted, the Availability Manager and SynQ Cockpit help identify the individual event, time and root cause. Elements that have affected the entire system’s availability in the last few days or weeks can be visually identified using the events log that captures all actions and events in the system automatically.

The Swisslog Availability Manager solution offers considerable added value over conventional simulation and measurement methods. “The software acts as a service provider within the logistics system,” says Stuart. “It ensures that the availability requirements can always be harmonized with the actual system availability and visualised instantly with SynQ Cockpit and visualisation tools.”

By automating this calculation through reported events in the event log, accuracy is automated rather than reviewed manually as part of operational service reviews.

“This gives you a state-of-the-art planning tool that allows you to verify whether the system can actually meet the requirements defined by your business processes,” Stuart adds. “Also, the measurement results are so accurate that any decisions regarding bonus payments or contractual penalties will be extremely objective.”

The Availability Manager also provides the opportunity to determine where maintenance should be focused and which errors need the most urgent attention. In the face of unexpected changes to overall conditions, the Availability Manager offers the opportunity to focus on high impact errors.

“For example, the software highlights the consequences a one-hour maintenance-related stoppage of a crane in your high-bay warehouse would have on the overall availability in your material flow system,” says Stuart.

Identifying key pinch points adds real value to maintenance operations and focuses on opportunities to scale material flow with appropriate system redundancy and fail-safes.

Part of the proven SynQ Manager family

As part of Swisslog’s SynQ platform for synchronized intelligence, the Availability Manager provides a modern software answer to the critical question of how to operate a warehouse efficiently and sustainably.

The Availability Manager application for SynQ is an individually combinable business intelligence services that Swisslog offers in its steadily growing software portfolio. This portfolio also includes Cockpit Manager, Swisslog‘s powerful tool for data collection and visualization. Additional plug-ins such as Condition Monitoring allow system operators to step into the world of analytics and system monitoring.

“A global food and beverage giant is already making use of the Availability Manager, with several other Swisslog customers interested in how software can optimize warehouse performance,” Stuart reveals.

Excellent perspectives for planning

The Availability Manager is constantly being enhanced with additional functionality by a dedicated Swisslog software team. The aim is to enable businesses to easily determine if their warehouse has sufficient capacity for order processing and how much additional throughput the system can handle. It also allows warehouse managers to obtain specific data on how much time is needed to process a specific order volume based on the planned resources.

“With just a touch of a button, you will soon be able to display the number of employees needed to process all orders to be picked by a specific point in time. In today’s challenging climate, companies must deliver the right orders to the right customers at the right time. Errors and delays in order fulfilment can have lasting negative impacts on the brand – but maintaining high stock levels ties up capital and affects flexibility,” Stuart concludes.

อัพเดตข่าวสารและบทความที่น่าสนใจในอุตสาหกรรมโลจิสติกส์ก่อนใคร ผ่าน Line Official Account @Logistics Mananger เพียงเพิ่มเราเป็นเพื่อน @Logistics Manager หรือคลิกที่นี่